Micro Dosing Devices

From mg to

+100 g

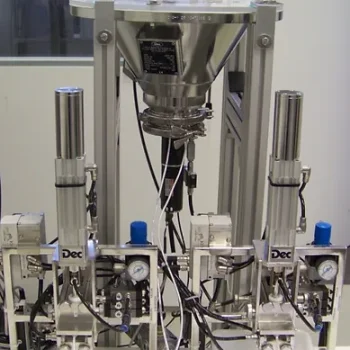

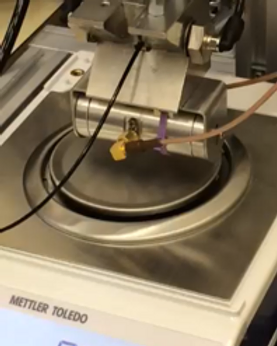

Microdosing devices are based on the PTS technology and allow precise and rapid dosing of very small quantities (< 1 mg) of powder in less than a second. High accuracy, up to 1% RSD, is achieved even with variations in bulk density, as the powder in the chamber is be pre-compacted by the vacuum effect.

Compared to typical mechanical dosing devices such as the Auger system, the various dosing devices can achieve higher accuracy on a larger range of quantities starting from 1 mg to few grams as the system is less influenced by powder property variations.

| µPTS vs Auger Influence on Accuracy |

µPTS | Auger |

|---|---|---|

| Bulk density | X | |

| Flowability | X | |

| Level of powder in hopper | X | |

| Lumps in product | X | |

| Particle size distribution | X | |

| Accuracy | 1% | 5% |

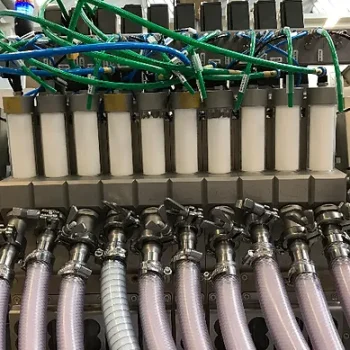

Depending on the quantities of powder to be dosed, Dec has developed different dosing systems to achieve the best performance in terms of accuracy, speed and investment.

| µPTS | flexPTS | sPTS | |

|---|---|---|---|

| Filtration | Filterless - dual µm slits | Filterless - dual µm slits / Metallic PTS membrance | Metallic PTS membrance |

| Dosing range | 1-500 mg | 200 mg -100 g | 100 g + |

| Speed | 1-4 seconds | 0.5-2 seconds | 5-20 seconds |

| Accuracy | 2 % rsd typ. | 3 % rsd typ. | 5 % rsd typ. |

| Dead Volume | No. | Yes, minimized | 5 % rsd typ. |

| Adapt | Coarse: swap chamber / Fine: change height of dosing chamber with linear motor | Coarse only: swap chamber | |