DCS® Docking System

High Containment big

bag filling

This space saving device can be easily connected below the process equipment to be discharged. It can be installed in a remote place in case of lacking head room below the equipment or when a number of process equipment are to be emptied through one single filling station.

In this case powder will be transferred by using PTS Powder Transfer System® and DosiValve® for accurate dosing, both of which are connected to the DCS® system.

The modular system can be designed to fill both drums with liners and big bags. It can also be combined with the MPTS Sampling Device for taking samples during the filling process.

- Integrated filter cartridge with or without back-flushing

- Ventilator

- Side discharge waste bag

- Load cells

- Bag compactor

- Various suction hoppers (delumper, fluidization cone, etc.)

- Integrated sieve

- Metal separator

- Vibrator

- CIP

- Suitable for ATEX zone 1/21

For higher containment requirements (0.1µg/m3), big bags can be fitted with a Rapid Transfer Port (RTP).

With safety always a priority, DCS® guarantees both primary and secondary containment, with a glove box enabling the operator to connect the liners within a sealed environment.

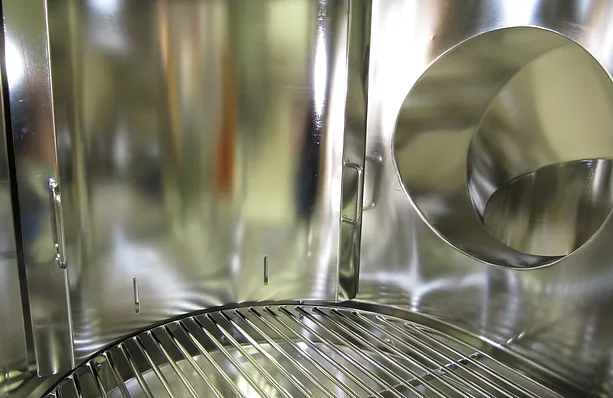

The fully cleanable DCS® system features a Push-Push HEPA filter which is connected to an extraction system.

System available in various materials (SS, HC22, Halar coated, etc.) and on load cells. Inertization possible. Appropriate for use in ATEX zone 1/21.

The fully cleanable DCS® system features a Push-Push HEPA filter which is connected to an extraction system.

System available in various materials (SS, HC22, Halar coated, etc.) and on load cells. Inertization possible. Appropriate for use in ATEX zone 1/21.

Download

Documentation Assessments Videos

> Please register or login

Documentation Assessments Videos

> Please register or login