Description

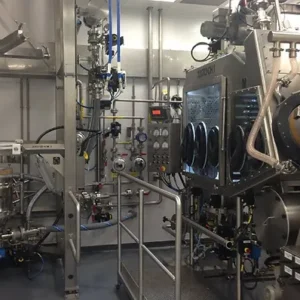

Isocharge is best described as a hybrid design, crossing laminar flow technology with a glove box isolator. It provides the operator with the protection of a gloved visor and the flexibility of an open laminar flow booth providing a high containment solution for rapidly dispensing and charging powders into any process. The system is designed to feed powder from bags or drums into process equipment whilst managing all contamination risks for both operators and the environment.

Isocharge for bags

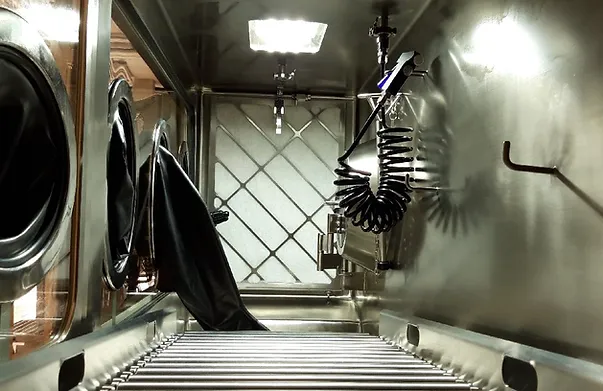

Isocharge for emptying bags consists of a stainless steel chamber which is open on one side, enabling easy loading of bagged powder. This principal feature allows powder to be loaded into the chamber and safely charged with the door open while achieving a high containment level of <1 µg/m3.

The open end is sized to provide an inlet air velocity of 0.7m/s; as the chamber size increases along its length, the air velocity steadily decreases until it levels out at approximately 0.2 – 0.3 m/s at the point of opening the bag of powder. This ensures that there is a one-way air transfer from the room, through the chamber, exhaust plenum, filters and fan, and finally out to the atmosphere.

This bullet-shaped chamber means that high containment is achieved with the door open and tests prove that containment is not improved any further by closing the door. Designed to be used by either one or two operators, the chamber is loaded through the open end of the main chamber, then gloves are used to open the bags and pour the powder into the discharge hopper, which is located in the chamber base. The base has an integrated discharge transition for mounting a suction hopper with a delumper if required.

For the safe removal of contaminated bags after emptying them into the hopper, Isocharge is supplied with an endless liner port with a cover fully integrated through the chamber base. The powder is then discharged from the hopper by means of the PTS mounted on the receiving vessel. The PTS controls are linked to the Isocharge’s control panel so that the operator does not have to move away from the charging area during operation. This turns out to another great advantage when a number of reactors needs to be charged with only one single station.

An access door (manual or automatic) is provided which is mostly used when the unit is not in operation or during cleaning to prevent splashes outside the chamber. It includes a wash gun to easily reach soiled areas of the chamber. The washing fluids are then either removed by PTS suction or via a draining.

Reviews

There are no reviews yet.